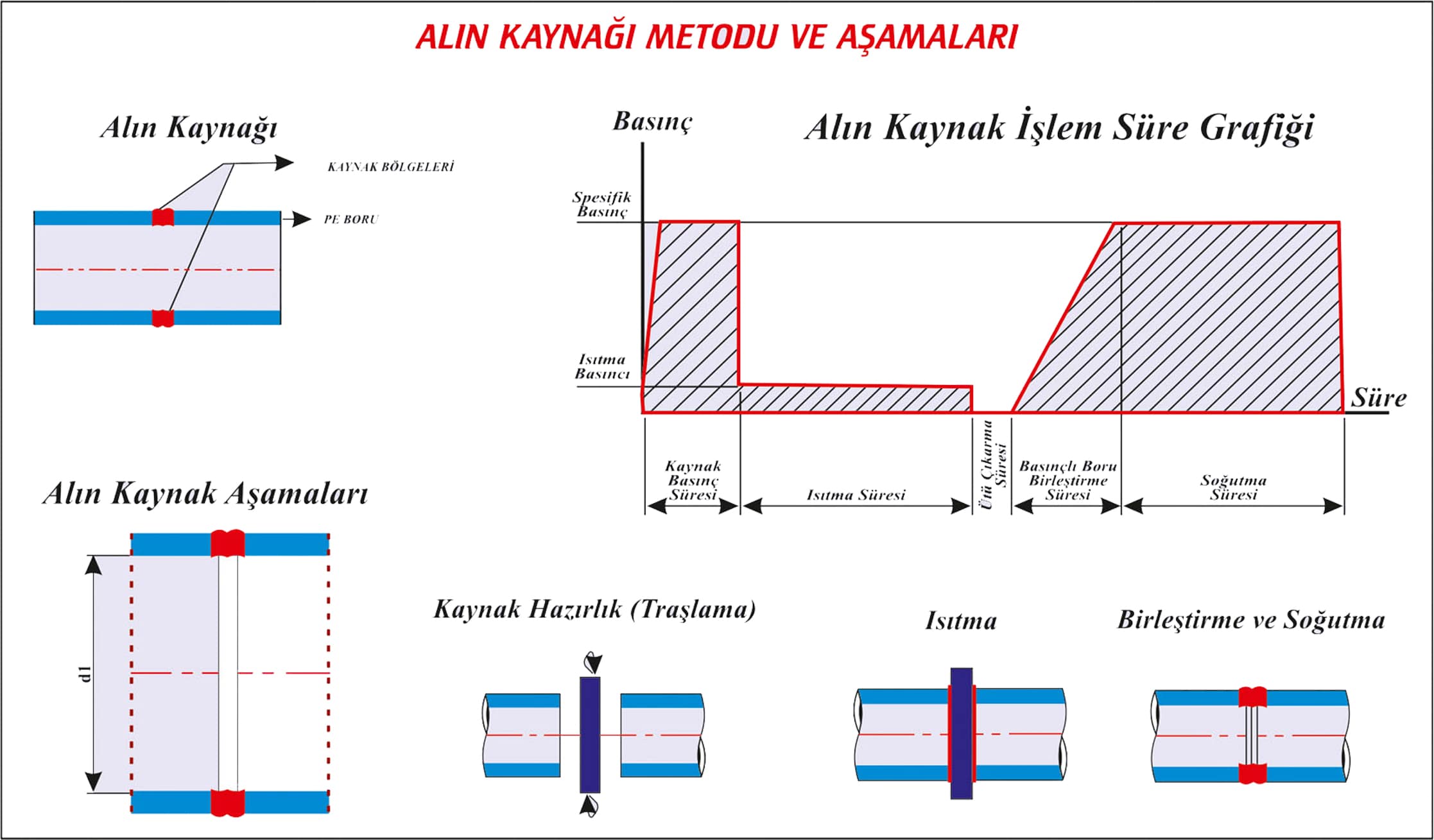

1. Butt Welding:

Polyethylene pipes can be produced to be combined by butt welding method according to the feature of the project to be applied. However, there are technical restrictions for both diameter and wall thickness in joining with this welding method. With this welding method, joining is made from a diameter of 50 mm to 1600 mm and from a minimum wall thickness of 5 mm to a wall thickness of 100 mm depending on the diameters. Butt welding process is carried out according to DVS 2207 standard.

Points to be considered in connecting PE pipes with butt welding;

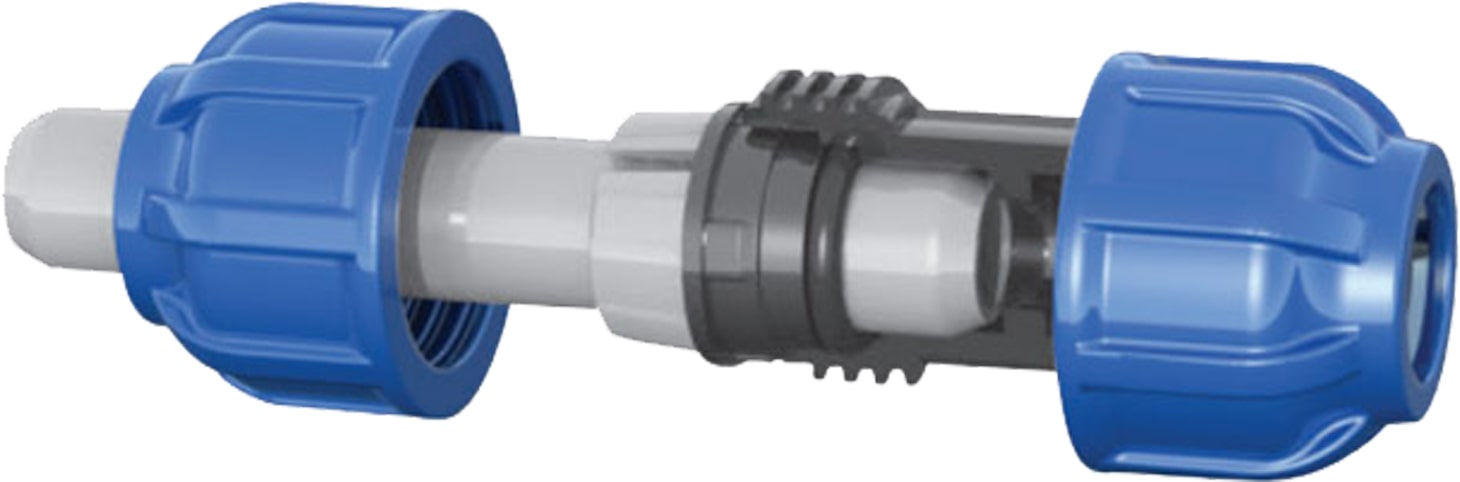

2. Joining with Coupling Couplers:

Mechanical coupling couplings are sometimes used for joining PE diameters between 20 and 125 mm. This method is preferred because it can be easily done with the help of conventional hand tools, can also be applied to wet pipe surfaces and does not require a welding machine or electricity. However, this method does not provide impermeability as high as a welding method.

Application:

3. Joining by Electrofusion Welding:

EF Welding is one of the joining methods of PE pipes. EF Couplers or fittings containing copper braces are used for welding. Electric current is given to the copper belts at the time and value determined by the manufacturers, and the heat generated in the belt region and its surroundings ensures that the PE pipe and EF fitting are welded to each other.

Preparation for Welding:

EF Before welding, the pipe length to enter EF fitting is measured with the help of a tape measure. Then this distance is marked on the pipe with a marker pen. Then the outer surface of the PE pipes is scraped with the help of a scrapper to remove the oxide layer. Afterwards, both the scraped surfaces and the inner surface of the EF fitting are wiped with an alcohol swab. Purpose is to clean oil and dirt residues on PE surfaces.

Welding Process:

Prepared pipes are passed into EF fitting. Then, in order to apply current to the EF fitting copper straps, the cables of the special machine made for EF welding are connected to the plugs located outside the EF fitting. Then, the barcode on the EF fitting is scanned into the barcode readers of these special welding machines and the EF fitting is introduced to the machine. After this process, the machine knows how much current will be applied to which fitting in what time.

The information on the machine screen is checked and if it is correct, the machine is started. The machine applies the current and cuts the current at the end of the time. The joint cannot be moved during the cooling of the heated surfaces. The resource is finished.